Our knowledge of plastic materials contributes most effectively to the development of products in the initial phase. We provide engineering, R&D and design services, for which we have several 3D printers at our disposal.

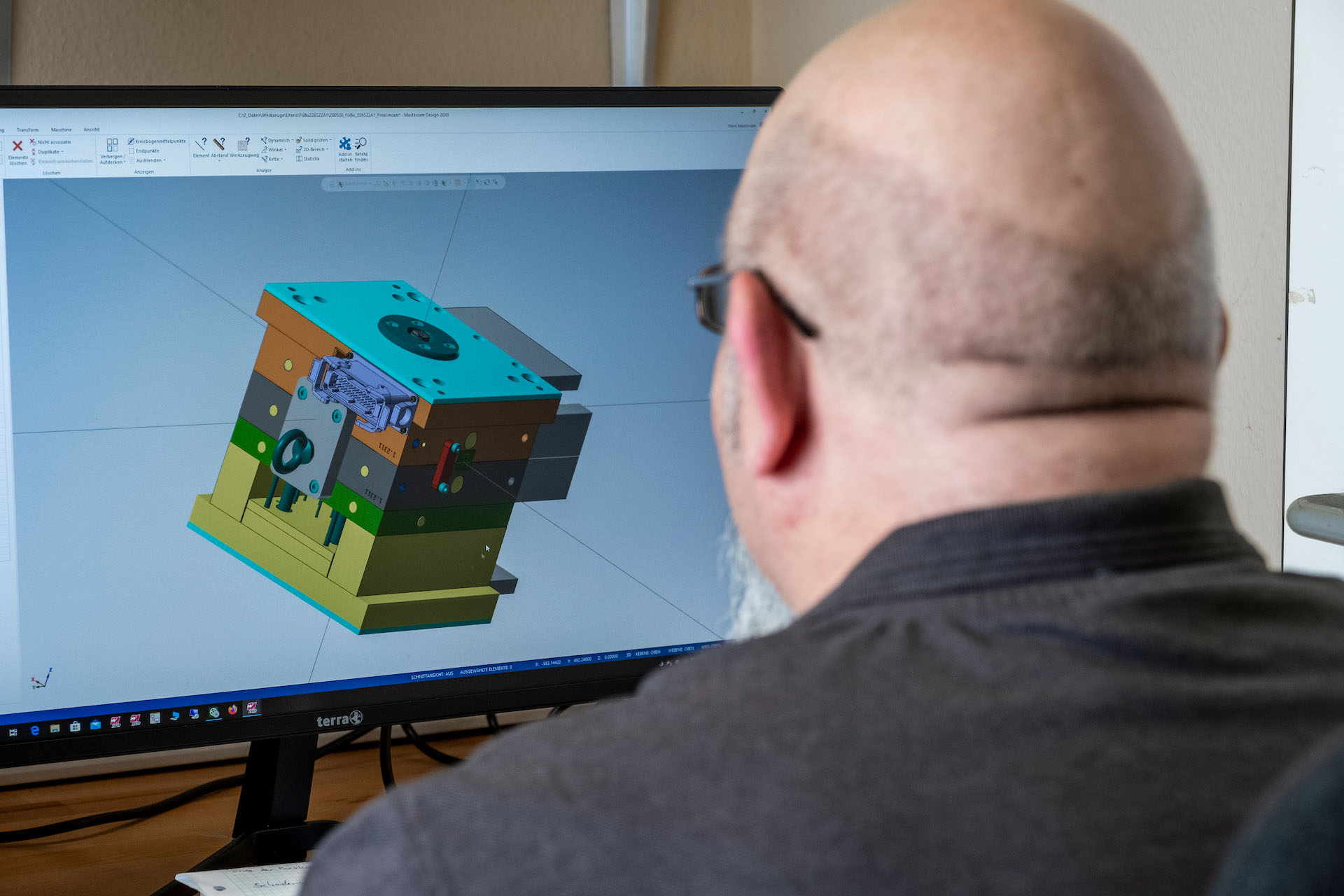

We have internal mould making departments at both De Beer Breidenbach and De Beer Beoplast. This makes us fast and flexible when it comes to building prototype moulds and/or series moulds.

We use our extensive knowledge of materials, from soft to hard and from commodity to very specific, during the development phase.

Both internally and in collaboration with raw material suppliers, we are able to perform various material tests and adapt materials for specific applications.

We employ more than 500 different types of material for our production and always have the majority of them in stock.

Business Development manager